Centrifuge Machine For Acceleration

Tarang’s Centrifuge Machine for Acceleration is purpose-built to examine the mechanical performance of parts and assemblies when subjected to varying linear acceleration forces. Its design begins with a robust outer enclosure, crafted to endure the substantial centrifugal forces generated during high-speed rotation. This enclosure not only shields the internal components and test specimens but also prioritizes operator safety, preventing accidental exposure to these extreme forces and ensuring a controlled testing environment.

At the core of this system lies a rotating platform, outfitted with two mounting plates that can securely hold a broad spectrum of payloads. Whether you’re testing small components like electronics boards or larger assemblies such as automotive sub-systems, the platform’s versatility allows precise positioning of each test specimen at specific radial distances. By adjusting the specimen’s radial placement, engineers can accurately establish the required acceleration level to replicate the real-world stresses these parts may encounter, such as those experienced in high-speed vehicles, aerospace applications, or other dynamic environments.

Power and control are provided by a permanent magnet brushless servo motor, chosen for its consistent torque delivery, low maintenance, and high efficiency. This motor is governed by a PWM amplifier coupled with a digital closed-loop control system, enabling operators to adjust rotational speed in fine increments while receiving continuous feedback for real-time data acquisition. This closed-loop feedback not only ensures the centrifuge runs at a stable speed throughout each test cycle but also allows for quick and precise modifications should testing parameters change mid-run.

To further enhance the machine’s utility, Tarang has designed it to comply with a variety of international standards, including IS, MIL, DIN, ISO, EN, IEC, DEF, JSS-55555, and ASTM. Such compliance is vital for industries like aerospace, automotive, defense, and electronics, where products must meet stringent certifications and safety requirements. By supporting these recognized standards, the centrifuge facilitates both research and validation testing, helping manufacturers and engineers prove their components’ reliability in demanding scenarios.

Linear Acceleration Machine 100g acceleration and 100Kg Payload capacity

Linear Acceleration Machine 100g acceleration and 100Kg Payload capacity

The wide acceleration range offered by Tarang’s Linear Acceleration Machines—extending from 1 mG to 1000 G, and 1 g-kg to 50000 g-kg—enables a vast array of testing possibilities. Engineers can simulate everything from ultra-light microgravity conditions up to extremely high acceleration scenarios that parts might face during rocket launches, missile deployments, or intense high-speed collisions. This high-precision capability is crucial for gathering detailed data on how components behave under different stresses, aiding in both product development and quality assurance.

For improved test monitoring, the centrifuge integrates a CCTV system, allowing continuous visual inspection of the test specimen throughout each run. This feature is particularly beneficial for documentation and troubleshooting, helping operators observe any potential distortions, vibrations, or anomalies in real time. Moreover, the machine supports multiple connectivity options—including electrical, electronic, data transfer, RF, pneumatic, and hydraulic interfaces. These connections accommodate live power feeds, sensor outputs, or fluid lines, ensuring test subjects can be evaluated under realistic working conditions, such as powered electronics, flowing hydraulics, or active pneumatic systems.

By merging durable construction, advanced control systems, comprehensive connectivity, and in-depth data capture, Tarang’s Centrifuge Machine for Acceleration offers a complete testing platform. It not only provides reliable insights into product performance, safety, and durability but also empowers engineers and researchers to optimize designs and uphold stringent quality standards. Whether it’s confirming the resilience of a critical aerospace component or validating the longevity of a newly developed automotive subsystem, Tarang’s solution stands as a cornerstone for industry-leading testing, innovation, and product excellence.

| Advantages for you |

Key features |

| Customizable Reliable Solutions |

- Rigid and robust structure

- Visual monitoring of Unit under test

- Electrical, Electronics, Pneumatic, Hydraulic terminals are available

- Capable to perform tests in accordance with various standards eg. IS,

MIL, DIN, ISO, EN, IEC, DEF, JS55555 & ASTM etc.

|

| Efficient performance |

|

| User Friendly |

|

Linear Acceleration Machine standard models

| Model |

TCAM - 250 |

TCAM - 500 |

TCAM - 1000 |

TCAM - 2500 |

| Acceleration Range |

1-50 ‘g’ |

1-100 ‘g’ |

1-100 ‘g’ |

1-200 ‘g’ |

| Nominal Radius |

300 m m |

700 m m |

750 m m |

1250 m m |

| Platform Radius

range |

250-350

mm |

500-900

mm |

550-950

mm |

750-1750

mm |

| Payload size |

100 mm cube |

400 mm cube |

400 mm cube |

1000 mm cube |

| Payload Capacity |

50 Kg |

50 Kg |

100 Kg |

250 Kg |

| No of Test Proiles |

1-100 |

1-100 |

1-100 |

1-100 |

| Max speed |

550 rpm |

350 rpm |

350 rpm |

400 rpm |

| Speed resolution |

.01rpm |

.01rpm |

.01rpm |

.01rpm |

| Dimensions |

Dia –

800mm

Height –

800mm |

Dia –

2000mm

Height –

2000mm |

Dia –

2000mm

Height –

2000mm |

Dia –

3600mm

Height –

2000mm |

| Mass |

1500 Kg |

2500 Kg |

3000 Kg |

5000 Kg |

| Online Testing

Connections

(Slip Ring) |

Electrical, electronic, Data transfer, RF, Pneumatic, Hydraulic connections

(Multiple connection configuration is available) |

| Utilities Required |

6-8 bar compressed air; 410V, 3-phase 50 Hz: earthing |

| Safety Interlocks |

Mains Input Over & Under Voltage, Phase drop,

Door Lock, Imbalance Vibration |

Note : Customized solutions are available

Specifications are subject to change without notice. It is the responsibility of the product user

to determine the suitability of this product for a specific application.

PC Based Instrumentation System

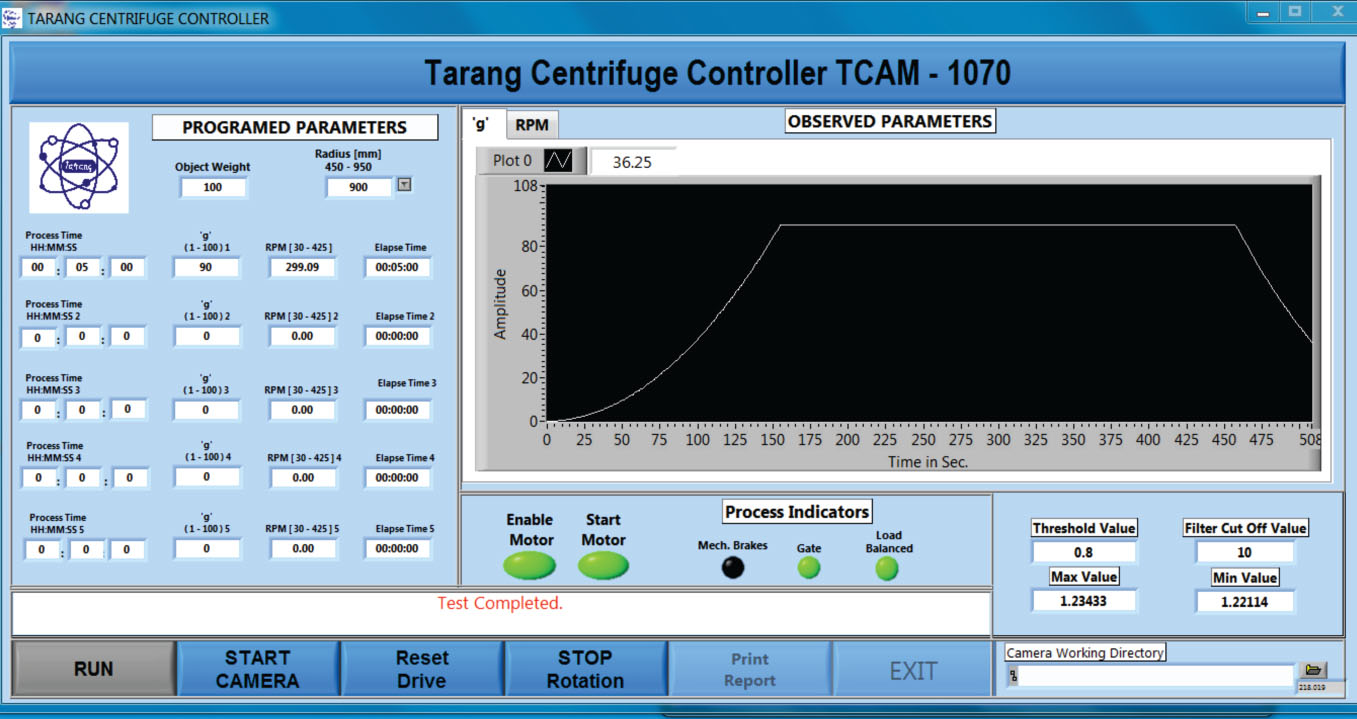

Tarang’s Acceleration Centrifuge Machine comes equipped with an advanced PC-based instrumentation system that provides precise control and monitoring of critical test parameters. This sophisticated setup streamlines the testing process by allowing users to easily configure and track variables such as rotation speed, acceleration (“g”), radius, test time cycle, and unit mass. Real-time feedback on these parameters ensures that test conditions can be quickly adjusted to meet specific application requirements.

A key element of this setup is the LABVIEW-based GUI application, which offers an intuitive interface for both configuration and visualization of performance data. Its data logging and analysis features enable in-depth evaluation of test results, helping operators refine test protocols and validate product performance. Additionally, the system incorporates safety interlocks—including imbalance detection and door-open monitoring—that are constantly supervised by an external PC running dedicated software, thereby ensuring safe operation throughout the testing cycle.

Screen shot of Centrifuge Machine for acceleration control and monitoring system

Screen shot of Centrifuge Machine for acceleration control and monitoring system

One of the notable advantages of this software is the ability to create and manage up to 100 programmable test profiles in a single session. This feature provides considerable flexibility for running multiple test sequences consecutively, each with its own set of parameters, without the need for extensive reconfiguration. By combining robust hardware with versatile software capabilities, Tarang’s Centrifuge Machine for Acceleration stands out as a reliable and efficient solution for industries demanding high-precision linear acceleration testing.

Download Product Catalogue