Free Fall type

This advanced testing machine is designed to accommodate a wide range of test objects, with weights ranging from 50 kg to 2000 kg. It provides precise control over acceleration, with a range from 3 "g" to 60 "g," and pulse durations from 3 ms to 20 ms, making it suitable for testing a variety of components and equipment under different conditions. The machine is specifically intended to replicate the effects of repetitive bumps, ranging from 60 to 180 bumps per minute, which are commonly experienced by objects during transportation or when installed in various classes of vehicles, such as trucks, cars, or other heavy-duty machinery.

By simulating these real-world transportation and operational conditions, this machine helps assess the durability, reliability, and performance of components, ensuring they can withstand the forces they are likely to encounter in service. This makes it an invaluable tool in industries such as automotive, aerospace, defense, and logistics, where the impact of transportation and installation vibrations on products must be thoroughly tested.

The machine is mounted on air springs, which provide excellent isolation and stability, reducing any external vibrations that may affect the testing process. Additionally, heavy-duty shock absorbers are incorporated to further isolate the machine from ground vibrations, ensuring that the test conditions remain consistent and accurate. This robust isolation system allows for precise testing and ensures that results reflect the true performance of the tested components under typical conditions.

Whether for research and development, quality control, or reliability testing, this machine provides a reliable and effective solution for simulating and evaluating the effects of repetitive bump forces on a wide range of test objects.

Bump Test Machine - 500 Kg Payload capacity

Bump Test Machine - 500 Kg Payload capacity

Force fall type

The machine is built with a highly durable, customized steel structure, ensuring exceptional strength and stability for a wide range of testing applications. It is specifically designed to accommodate test objects weighing between 50 kg and 2000 kg, offering flexible testing capabilities with acceleration ranging from 3 "g" to 200 "g" and pulse durations from 3 ms to 30 ms. This broad range of acceleration and pulse duration makes it suitable for testing components and equipment in various industries, including automotive, aerospace, and electronics, ensuring reliable performance under dynamic conditions.

The platform features a standardized object mounting hole pattern arranged in a 100 x 100 mm matrix, providing flexibility in positioning test specimens. For customized testing needs, the hole pattern can be tailored to meet specific customer requirements, offering an adaptable solution for different object sizes and mounting configurations. This level of customization ensures that the machine can accommodate a wide variety of test objects, enhancing its versatility and making it an ideal choice for testing complex or non-standard components.

This robust steel structure not only supports the machine's weight capacity but also ensures that it can withstand the forces generated during testing without compromising the accuracy or integrity of the test results. The combination of heavy-duty construction, customizable mounting options, and wide-ranging testing parameters makes this machine a reliable and flexible solution for simulating real-world conditions and assessing the durability and performance of test objects across multiple industries.

Description

The mounting platform is vertically raised using a precision Cam arrangement, allowing it to be elevated to the required height. Once lifted, the platform is then released to drop freely or with controlled force onto an Elastomeric pad, commonly known as a Half-Sine Programmer Pad, which is strategically placed on an anvil. This interaction generates the desired acceleration level for the test object. By adjusting the drop height of the mounting platform, the system can accurately control the impact acceleration, offering precise customization for different testing requirements.

The Elastomeric pads play a crucial role in shaping the characteristics of the vibration pulse. Specifically designed to produce half-sine pulses, these pads ensure that the acceleration profile mimics real-world conditions in a controlled manner. The duration of the pulse is adjustable, providing further flexibility in the testing process. This can be fine-tuned by modifying the hardness and thickness of the rubber pads, which directly influence the pulse duration and the energy delivered to the test specimen.

This level of adjustability ensures that the system can accommodate a wide range of testing scenarios, from light-duty applications requiring shorter pulses to more rigorous tests demanding longer pulse durations. The ability to fine-tune both the acceleration and pulse duration through simple adjustments makes this system highly versatile and capable of meeting the diverse needs of various industries, including automotive, aerospace, and electronics. This flexibility ensures accurate and repeatable test results, essential for validating the durability and performance of components under dynamic conditions.

| Advantages for you |

Key features |

| Customizable Reliable Solutions |

|

| Efficient performance |

|

| User Friendly |

|

Bump Test Machine standard models

| Model |

TBTM - 6060 |

TBTM - 7575 |

TBTM - 1005 |

TBTM - 1010 |

TBTM – 6060F |

| Type |

Free Fall |

Free Fall |

Free Fall |

Free Fall |

Force Fall |

| Table Size |

600 x 600 mm |

750 x 750 mm |

1000 x 1000 mm |

1000 x 1000 mm |

600 x 600 mm |

| Payload Capacity |

200 Kg |

350 kg |

500 kg |

1000 kg |

500 kg |

| Payload Height |

unlimited |

unlimited |

unlimited |

unlimited |

unlimited |

| Max Payload Size |

600 x 600 mm |

750 x 750 mm |

1000 x 1000 mm |

1000 x 1000 mm |

600 x 600 mm |

| Acceleration* |

3-60 g |

3-60 g |

3-60 g |

3-60 g |

3-200 g |

| Pulse Duration* |

3-18 ms |

3-18 ms |

3-18 ms |

3-18 ms |

3-30 ms |

| Pulse Shape |

Half-Sine |

Half-Sine |

Half-Sine |

Half-Sine |

Half-Sine |

| Standard Test** |

3’g’ – 10’ms’

7’g’ – 10’ms’

20’g’ – 11’ms’

30’g’- 6’ms’

40’g’ - 6’ms’ |

3’g’ – 10’ms’

7’g’ – 10’ms’

20’g’ – 11’ms’

30’g’- 6’ms’

40’g’ - 6’ms’ |

3’g’ – 10’ms’

7’g’ – 10’ms’

20’g’ – 11’ms’

30’g’- 6’ms’

40’g’ - 6’ms’ |

3’g’ – 10’ms’

7’g’ – 10’ms’

20’g’ – 11’ms’

30’g’- 6’ms’

40’g’ - 6’ms’ |

20’g’ – 11 ’ms’

40’g’ - 6’ ms’

50’g’ – 18 ’ms’

100’g’ – 6’ ms’

200’g’ – 3’ ms’ |

| Bump Rate |

1-3 bumps/sec |

1-3 bumps/sec |

1-3 bumps/sec |

1-3 bumps/sec |

1-3 bumps/sec |

| Max Drop Height |

50 mm |

50 mm |

50 mm |

50 mm |

50 mm |

| Max

Deviation of

specimen

from table

centre |

15 mm |

15 mm |

20 mm |

20 mm |

15 mm |

| Machine Mass |

2700 kg |

3000 kg |

3500 kg |

4000 kg |

4800 kg |

| Dimensions |

1500x1500x950 |

1500x1500x950 |

1600x1600x1000 |

1600x1600x1000 |

1500x1500x1000 |

| Utilities required |

6-7 bar compressed air, Earthing, 3-phase Power |

| Safety Interlocks |

Mains Input Over & Under Voltage, Phase drop, programmer pad change protection, over travel |

* Higher 'g' at lower 'ms' and lower 'g' at higher 'ms'

** Various other bump tests can be conducted other than the ones listed above

Note : Customized solutions are available

Specifications are subject to change without notice. It is the responsibility of the product user

to determine the suitability of this product for a specific application.

Bump Monitoring and Control System

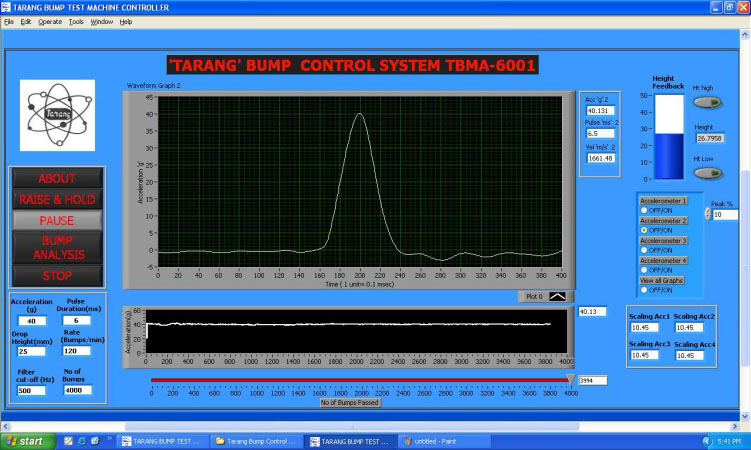

The Tarang Digital Bump Monitoring System, Model TBMA 6001, is an advanced, PC-based intelligent instrumentation solution specifically designed for the on-line control and monitoring of bump vibration severity on test objects mounted on the Tarang Bump Test Machine. This system is built to provide a seamless and intuitive user experience, with an easy-to-operate interface that allows for straightforward configuration of essential input parameters. Whether used for routine testing or more specialized applications, the system ensures that the bump vibration tests are carried out with precision and reliability.

The TBMA 6001 system displays all relevant parameters in real-time, including pulse height (acceleration), pulse duration, corresponding velocity change, and bump counts. These key metrics are presented in a clear numerical format on the screen for all four channels simultaneously, providing operators with a comprehensive view of the test conditions. This continuous monitoring ensures that the system remains within desired operational thresholds, allowing for timely adjustments if needed.

Screenshot of Bump Test Machine control and monitoring system

Screenshot of Bump Test Machine control and monitoring system

Additionally, the Tarang Bump Test Machine is engineered to be extremely user-friendly, with an interface designed to simplify the process of setting and adjusting input parameters. The ability to easily modify the test parameters ensures that users can quickly adapt the system to different testing requirements, whether for quality control, research and development, or validation of component durability under bump vibration conditions.

By offering real-time data visualization and control for all four channels simultaneously, the Tarang Digital Bump Monitoring System enables precise analysis of bump vibration severity. This ensures that the test object is subjected to accurate, reproducible testing conditions, making it an ideal choice for industries such as automotive, aerospace, and electronics. The system's ability to display multiple test parameters in one view allows operators to efficiently manage the testing process, enhancing productivity while ensuring that all necessary metrics are closely monitored for optimal performance and test accuracy.

Download Product Catalogue